Feb 17,2023

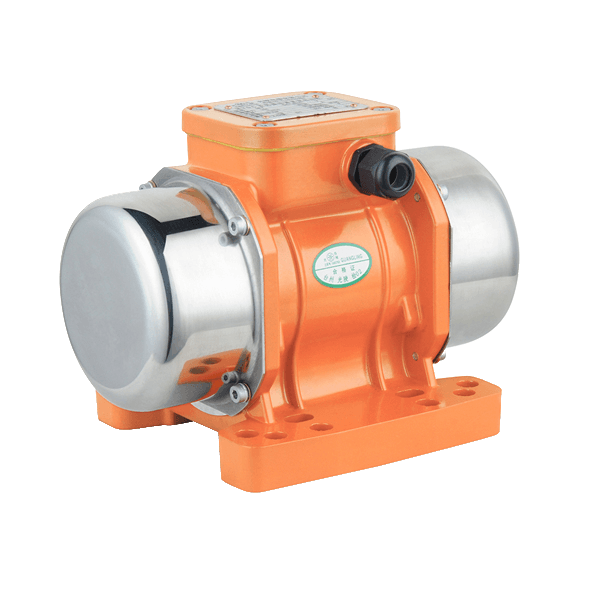

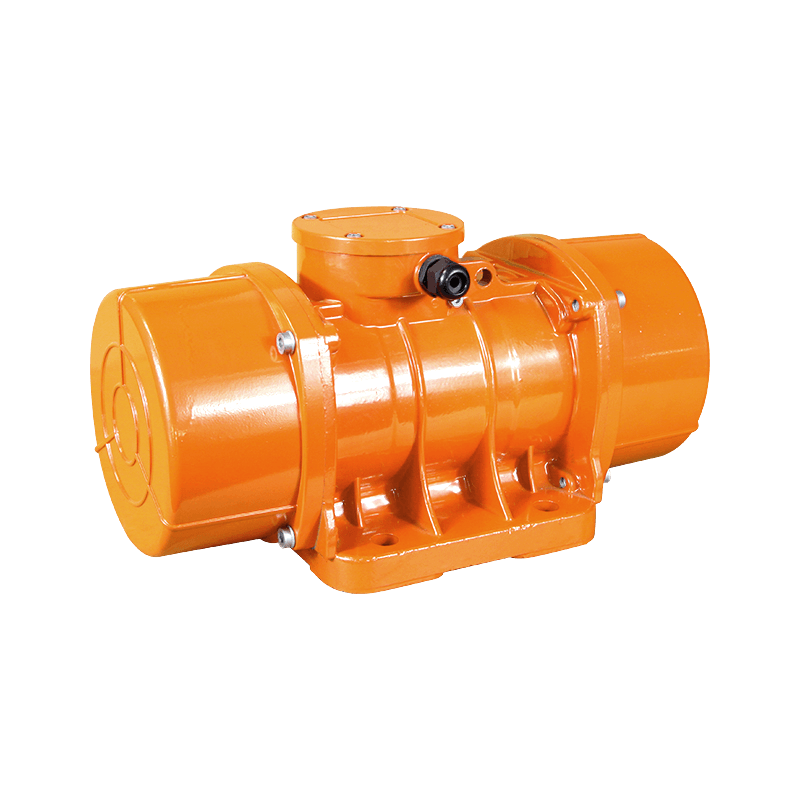

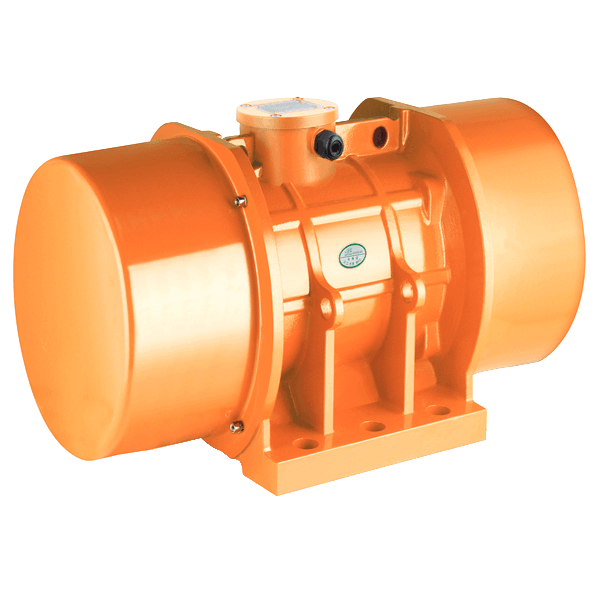

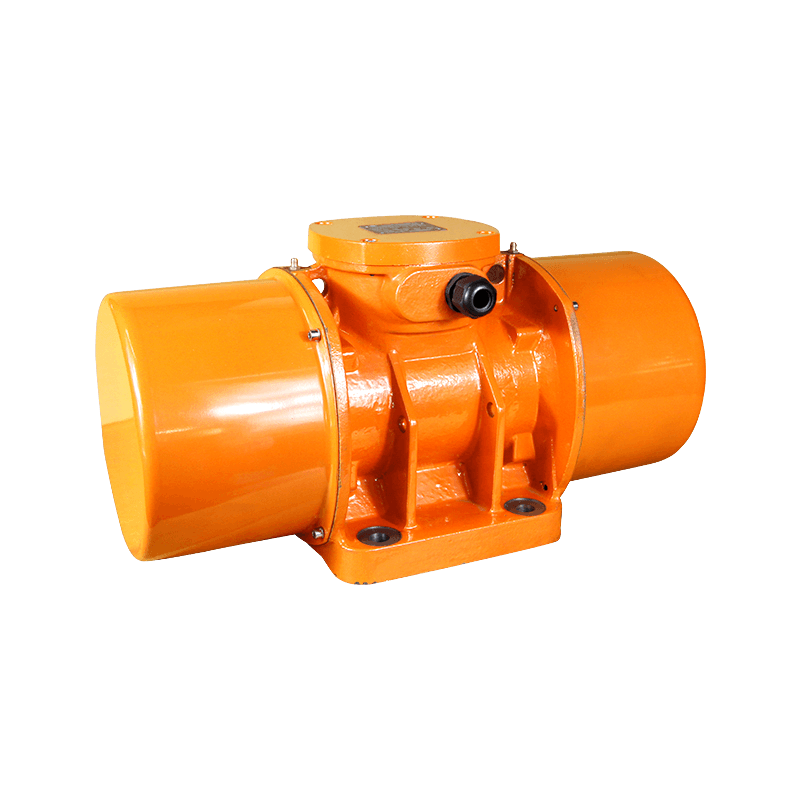

They can be used with a wide variety of materials, including dry powders and wet concrete. They are durable and energy-efficient, and they use reliable and economic electric power to operate.

Vibrating vibrators can improve the flow of bulk materials. They can help solve problems like bridging, ratholing or clumping in bins and hoppers.

Choosing the right type of vibrator for your application is based on the materials you handle. If you are handling dry and powdery materials, a rotary vibrator may be the best option. However, if you are handling wet or sticky materials, a pneumatic option would be better.

These vibrators are available in a range of different models and features to suit your needs. They are ideal for a number of industries, including mining and quarrying, food processing and chemical manufacturing.

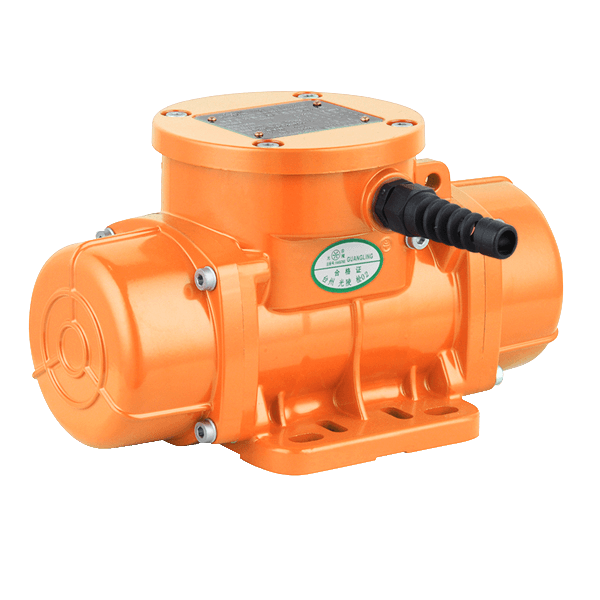

The vibration motor is a device that is designed to transmit an alternating current through the magnetic field of a permanent magnet. This electric voltage is then supplied to a voice coil to generate a mechanical force that causes the vibrating motor to move.

This force can be altered by the mass attached to the shaft, the distance of that mass from the rotor, and the speed at which it is turning. The resulting centrifugal strength produces high-speed dislocation in two axes of the vibrating motor.

英语

英语 葡萄牙语

葡萄牙语 西班牙语

西班牙语 русский

русский

Tel: + 86-576-86320988

Tel: + 86-576-86320988

Fax: + 86-576-86333217

Fax: + 86-576-86333217

E-mail:

E-mail:  Add: Dayangcheng Industrial Zone, daxi, wenling, zhejiang, china

Add: Dayangcheng Industrial Zone, daxi, wenling, zhejiang, china