Mar 24,2023

The performance of an electric vibrator motor is affected by a number of characteristics, including electrical, magnetic, and mechanical coupling effects. In particular, the current and displacement of a vibrating motor are strongly influenced by these characteristics.

In this research, an electric vibrating motor was modeled and analyzed using a numerical iteration method combined with FEM to determine the current and displacement. In addition, the nonlinear parameters, such as inductance, speedance, and force factor, were considered to analyze the performance of the electric vibrating motor.

Many industrial applications are aided by the use of vibrating equipment. For example, a rotary electric vibrator can be used to sift and sort material in a screening machine, empty hoppers thoroughly of sticky or wet material, keep material flowing through chutes at transfer points, and loosen adhesion in silos.

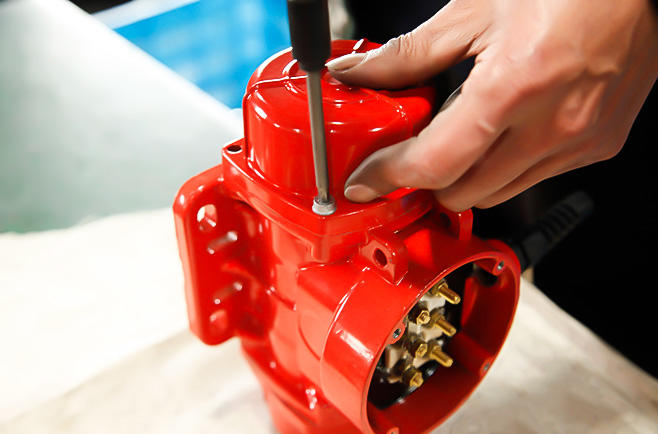

The MVE series of external electric vibrators are ideal for these applications, featuring a cast casing with eccentric weights fitted on both shaft ends. These motors are available in 2, 4, 6 and 8 pole designs, with a variety of voltage options and a centrifugal force ranging from 20 to 30,000 kg, adjustable on each individual model. They are also available in direct current, and are suitable for use with inverters (variable frequency drive).

英语

英语 葡萄牙语

葡萄牙语

Tel: + 86-576-86320988

Tel: + 86-576-86320988

Fax: + 86-576-86333217

Fax: + 86-576-86333217

E-mail:

E-mail:  Add: Dayangcheng Industrial Zone, daxi, wenling, zhejiang, china

Add: Dayangcheng Industrial Zone, daxi, wenling, zhejiang, china