May 05,2023

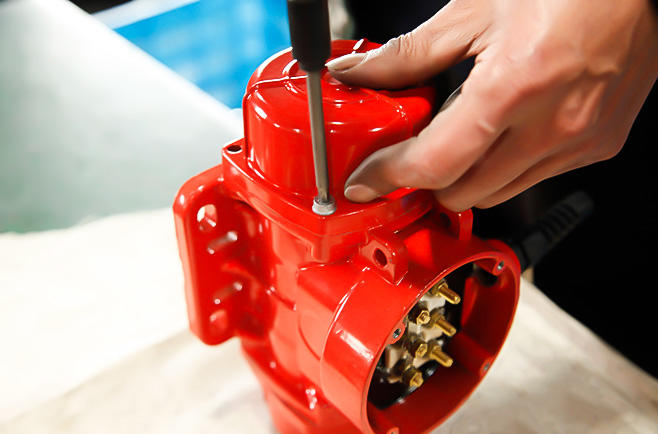

The construction work vibrator motor is a type of electric power tool used to compact concrete and remove air bubbles. They come in a variety of designs, sizes and operating conditions.

There are several different types of construction work vibrator motors, including flexible-shaft, pneumatic, and motor-in-head models. Each has its own advantages and disadvantages, but there are certain things you can look for to ensure you’re getting the right one for the job.

Advantages of Flexible Shaft Models

Flexible-shaft vibrators are a great choice for contractors who need a wide range of head sizes, amplitudes and frequencies. They can also be fitted with quick-disconnect systems, which reduce downtime and speed equipment changeovers.

Pneumatic Vibrators

Unlike their flexible-shaft counterparts, pneumatic vibrators use an air compressor as the power source. They’re less susceptible to motor damage than flexible-shaft and other motor-in-head models, but they do have their disadvantages.

They can lose power if other tools on the jobsite use the same air compressor. For this reason, it’s a good idea to have a dedicated air compressor for the vibrator.

Motor-In-Head Models

Unlike their flexible-shaft counterparts, motor-in-head vibrators have an electric or gasoline-powered motor inside the head. They are typically used on large, high-volume concrete jobs where the vibration frequency can’t be altered to accommodate other tools.

英语

英语 葡萄牙语

葡萄牙语

Tel: + 86-576-86320988

Tel: + 86-576-86320988

Fax: + 86-576-86333217

Fax: + 86-576-86333217

E-mail:

E-mail:  Add: Dayangcheng Industrial Zone, daxi, wenling, zhejiang, china

Add: Dayangcheng Industrial Zone, daxi, wenling, zhejiang, china