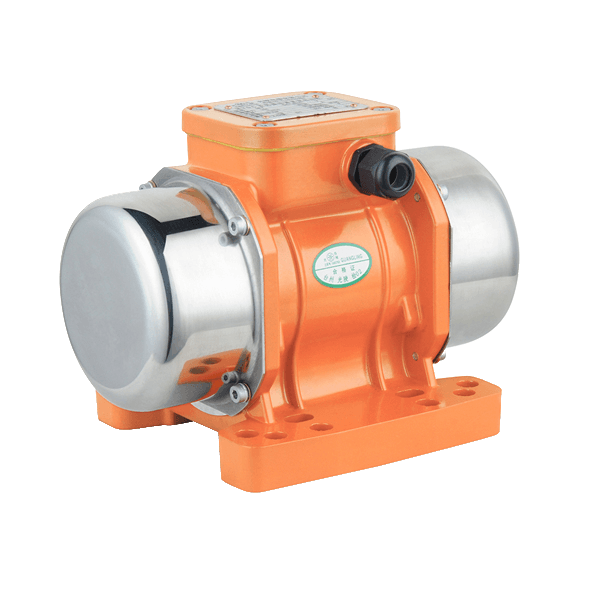

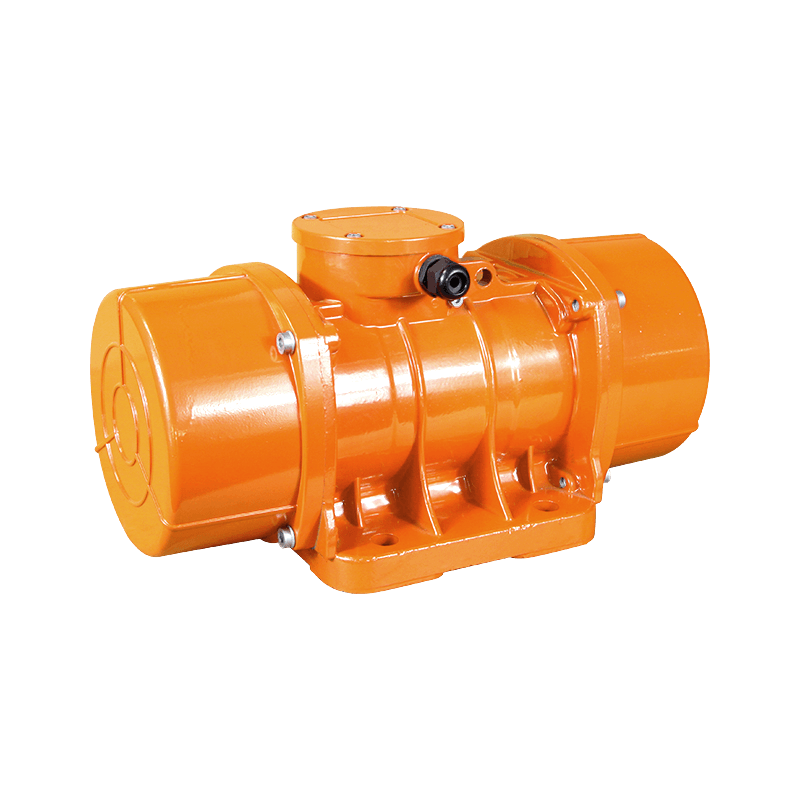

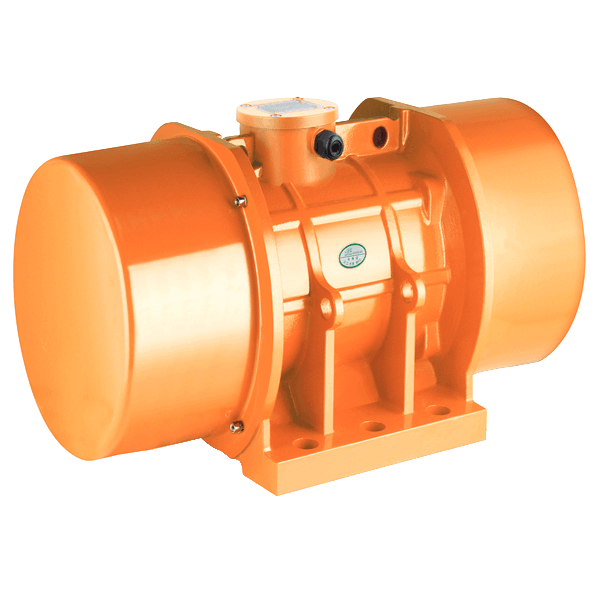

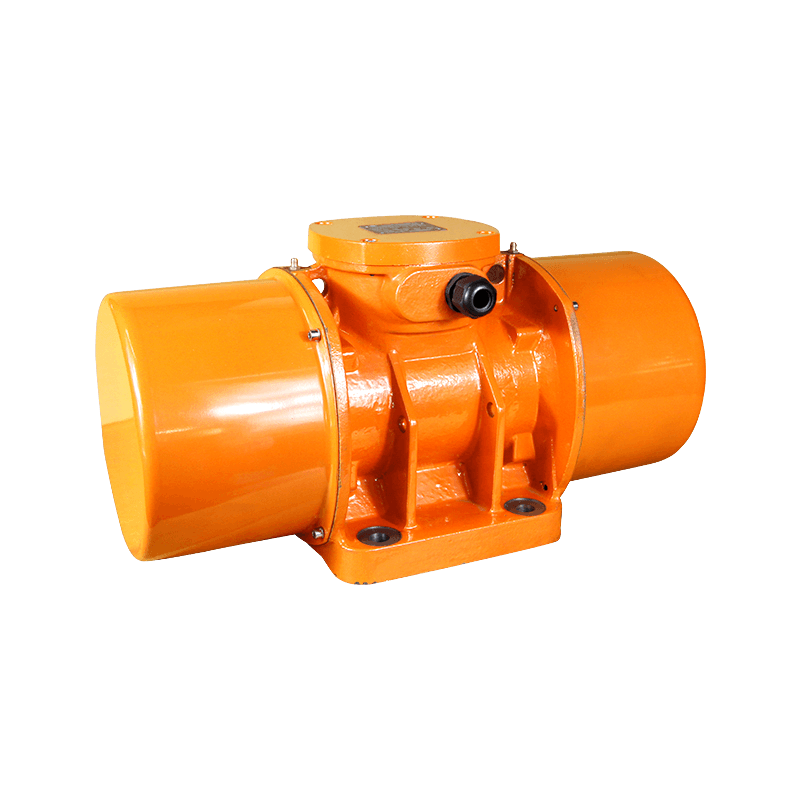

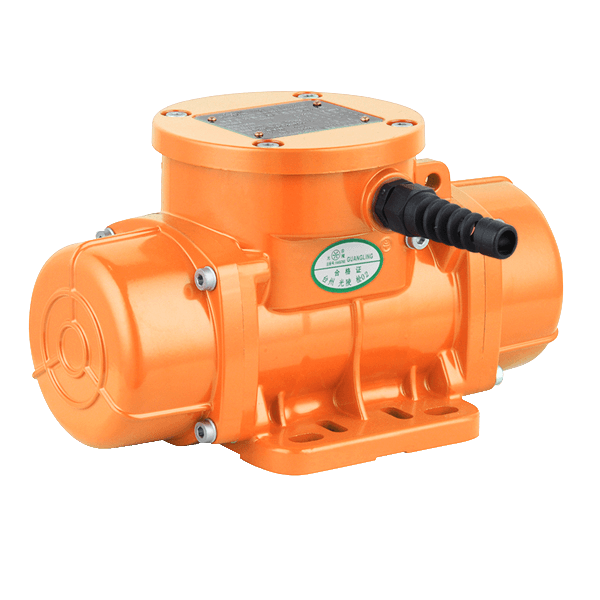

The integration of cutting-edge technologies is transforming industries such as mining, chemical refining, construction, and material handling. A key innovation contributing to these advancements is the mini waterproof electric vibration motor. These compact yet powerful motors have become indispensable across a wide range of industrial applications due to their versatility, reliability, and ability to withstand harsh environments. From mining operations to mixing stations and conveyor belt systems, the mini waterproof electric vibration motor is making a significant impact on industrial efficiency and productivity.

Mining Industry: Enhancing Material Handling and Processing

In the mining industry, the efficient transport and sorting of raw materials are critical to maintaining high productivity levels. Mini waterproof electric vibration motors are used in vibrating feeders, screens, and hoppers, where their ability to provide continuous vibration ensures smooth and consistent material flow. These motors help move mined materials from one processing stage to another, ensuring that they are sorted, screened, and delivered to crushers, mills, and other processing equipment without blockages or delays.

For example, in vibrating screens, mini waterproof electric vibration motors are used to separate different sizes of materials, allowing for efficient sorting. This is especially important in the mining industry, where precise sorting and grading of materials can greatly impact the overall efficiency of the operation. These motors are able to handle large quantities of material while operating efficiently, ensuring that productivity remains high throughout the day.

In addition, mini waterproof electric vibration motors are critical in feeding systems that move materials from storage areas to processing units. The ability of these motors to maintain a steady and controlled flow helps reduce downtime caused by material blockages, ensuring continuous operation and improving overall efficiency in mining operations.

Chemical Refining: Precision in Material Transport and Mixing

Chemical refining processes demand a high level of precision, and this is where the mini waterproof electric vibration motor shines. These motors are commonly used in material handling systems such as feeders, hoppers, and vibrating conveyors, where their vibration helps move raw chemicals and intermediate products to the next stage of processing. The mini waterproof electric vibration motor ensures that materials move smoothly and consistently, reducing the risk of clogs and maintaining continuous flow.

In addition to transportation, mini waterproof electric vibration motors are also used in mixing stations within chemical refineries. For instance, when blending chemical compounds or other materials, these motors apply a controlled vibration to ensure thorough mixing and prevent material separation. This is particularly important when working with viscous liquids or powders that may tend to clump. The steady, even vibration provided by these motors ensures that all ingredients are well-mixed, resulting in a consistent final product.

Moreover, the waterproof capabilities of these motors are crucial in chemical environments where exposure to liquids or humid conditions is common. The mini waterproof electric vibration motor is designed to function effectively even in these challenging settings, making it an invaluable tool in the chemical refining industry.

Construction Machinery: Efficient Vibration for Concrete and Soil Compaction

The construction industry relies on a variety of vibrating machinery to improve the quality of materials and ensure the stability of structures. Mini waterproof electric vibration motors are commonly used in concrete vibrators and soil compactors, where they apply controlled vibrations to ensure that materials are uniformly mixed or compacted.

In concrete mixing stations, mini waterproof electric vibration motors help to eliminate air pockets and voids in the concrete, ensuring that the mixture is dense and durable. The vibration prevents the concrete from becoming uneven, improving the overall structural integrity of buildings, roads, and bridges. These motors can also be used in vibrators that ensure the smooth flow of concrete into molds, reducing the risk of flaws or defects in the final structure.

Similarly, in soil compaction, mini waterproof electric vibration motors help achieve uniform compaction, which is critical for creating stable foundations for construction projects. The consistent vibration provided by these motors helps soil particles settle evenly, improving the strength and stability of the foundation.

英语

英语 葡萄牙语

葡萄牙语 西班牙语

西班牙语 русский

русский

Tel: + 86-576-86320988

Tel: + 86-576-86320988

Fax: + 86-576-86333217

Fax: + 86-576-86333217

E-mail:

E-mail:  Add: Dayangcheng Industrial Zone, daxi, wenling, zhejiang, china

Add: Dayangcheng Industrial Zone, daxi, wenling, zhejiang, china