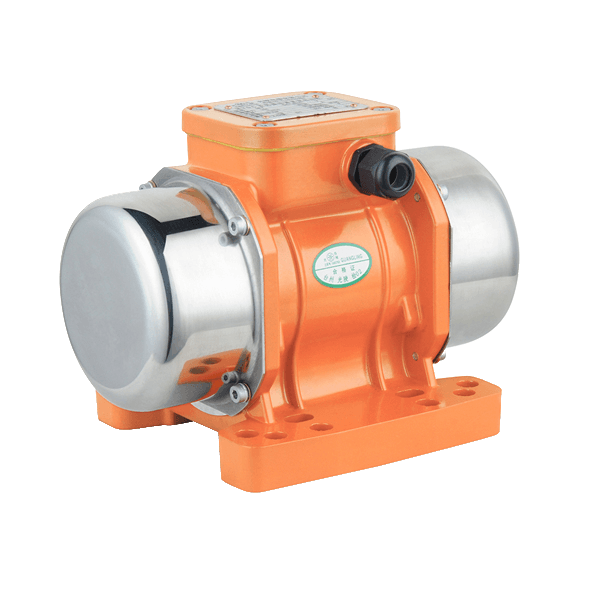

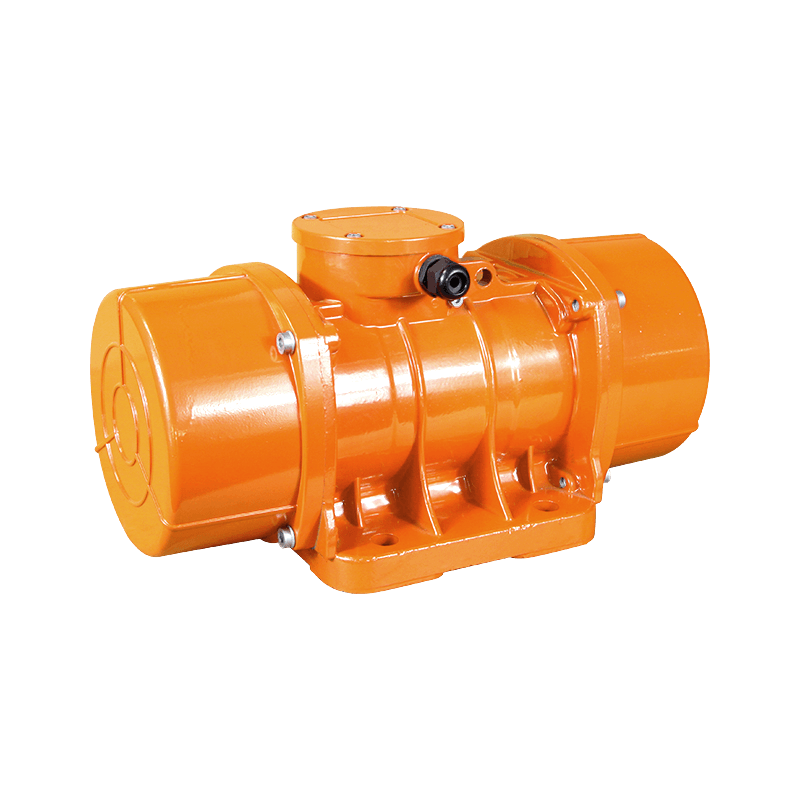

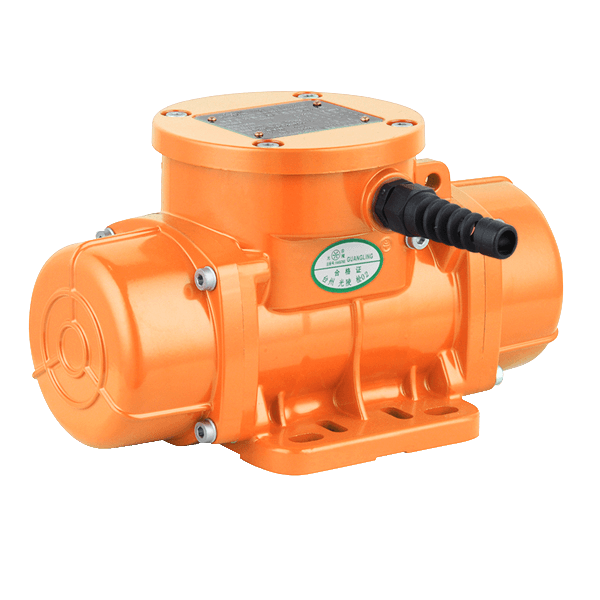

As we delve into 2024, the mini waterproof vibration electric motor sector is making significant strides, driven by advancements in technology and growing demand across various applications. These compact, efficient motors are increasingly used in diverse industries, from consumer electronics to automotive, and their waterproof feature adds to their versatility. This article explores the latest trends, innovations, and future prospects for mini waterproof vibration electric motors.

Expanding Applications

Mini waterproof vibration electric motors are gaining traction in numerous sectors due to their compact size and robust performance. One of the prominent applications is in the consumer electronics industry, particularly in smartphones, wearables, and gaming devices. As manufacturers strive to create more immersive user experiences, the demand for vibration motors that can provide tactile feedback is surging. These motors enhance functionalities such as alerts, notifications, and gaming experiences, making devices more interactive.

In the automotive sector, mini waterproof vibration motors are becoming essential for various applications, including alarm systems, navigation prompts, and driver assistance technologies. As vehicles become smarter, the need for reliable vibration feedback grows. These motors can withstand the harsh conditions often encountered in automotive environments, making them a preferred choice for manufacturers aiming to improve vehicle safety and functionality.

Another critical area where these motors are making an impact is in medical devices. From handheld diagnostic tools to wearable health monitors, the reliability and compactness of mini waterproof vibration electric motors enable efficient operation in sensitive applications. Their waterproof feature is particularly valuable in medical environments, where sanitation and reliability are paramount.

Technological Innovations

The mini waterproof vibration motor industry is characterized by continuous technological innovations. Manufacturers are focusing on improving efficiency, performance, and durability. Recent advancements include the development of brushless DC motors, which offer higher efficiency and longer lifespans compared to traditional brushed motors. These motors not only reduce power consumption but also minimize maintenance needs, making them ideal for long-term applications.

Additionally, the integration of smart technologies into these motors is transforming their functionality. Many modern mini waterproof vibration motors are equipped with sensors that enable real-time monitoring and feedback. This allows manufacturers to collect valuable data on motor performance, to better product designs and optimized applications. The ability to track usage patterns and predict maintenance needs can significantly reduce downtime and enhance overall system efficiency.

Sustainability and Energy Efficiency

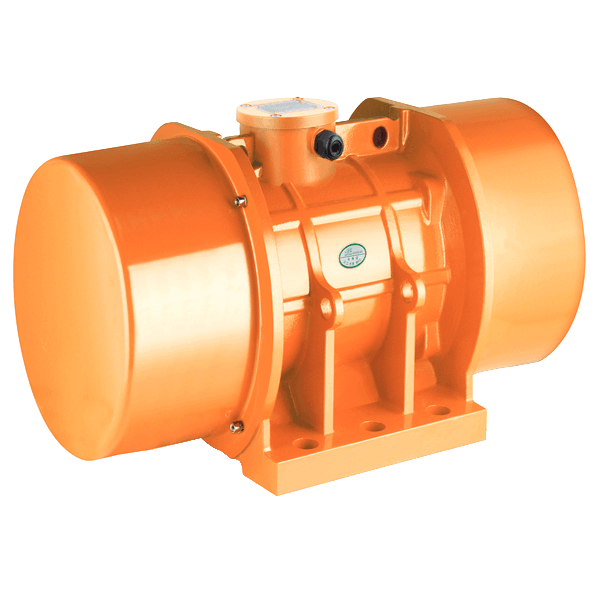

Sustainability is becoming a driving force in the design and production of mini waterproof vibration electric motors. Manufacturers are increasingly prioritizing energy-efficient solutions to reduce environmental impact and meet regulatory standards. These motors are designed to consume less power while delivering high performance, which is crucial in a market that demands both efficiency and eco-friendliness.

Moreover, the move towards sustainable materials is gaining momentum. Manufacturers are exploring the use of recyclable and biodegradable materials in motor production. This aligns with the broader industry trend toward sustainability, where companies are held accountable for their environmental footprint. By incorporating eco-friendly practices, manufacturers can appeal to environmentally conscious consumers while complying with increasingly stringent regulations.

Challenges Facing the Industry

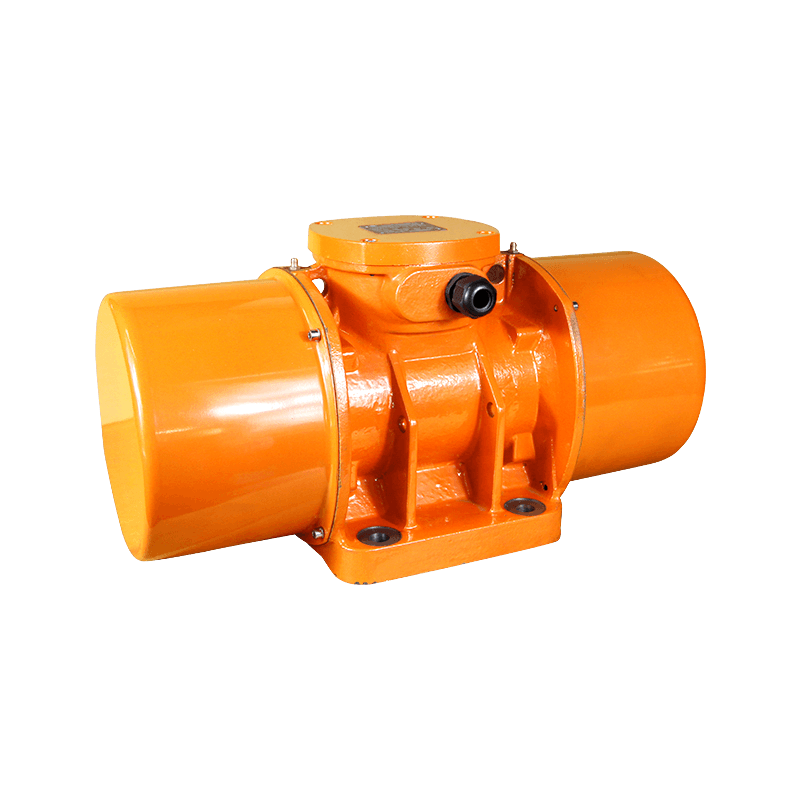

Despite the promising trends, the mini waterproof vibration electric motor industry faces several challenges. One of the primary concerns is the rising cost of raw materials, which can affect production costs and profit margins. Fluctuations in material availability can to delays in manufacturing and delivery. To mitigate these challenges, manufacturers are exploring local sourcing options and developing long-term relationships with suppliers to ensure a steady flow of materials.

Additionally, the complexity of modern applications requires a skilled workforce capable of designing and maintaining advanced vibration systems. As technology continues to evolve, the demand for skilled engineers and technicians is growing. Companies are investing in training programs to equip their workforce with the necessary skills to work with new technologies and maintain high standards of quality.

英语

英语 葡萄牙语

葡萄牙语 西班牙语

西班牙语 русский

русский

Tel: + 86-576-86320988

Tel: + 86-576-86320988

Fax: + 86-576-86333217

Fax: + 86-576-86333217

E-mail:

E-mail:  Add: Dayangcheng Industrial Zone, daxi, wenling, zhejiang, china

Add: Dayangcheng Industrial Zone, daxi, wenling, zhejiang, china