Oct 14,2021

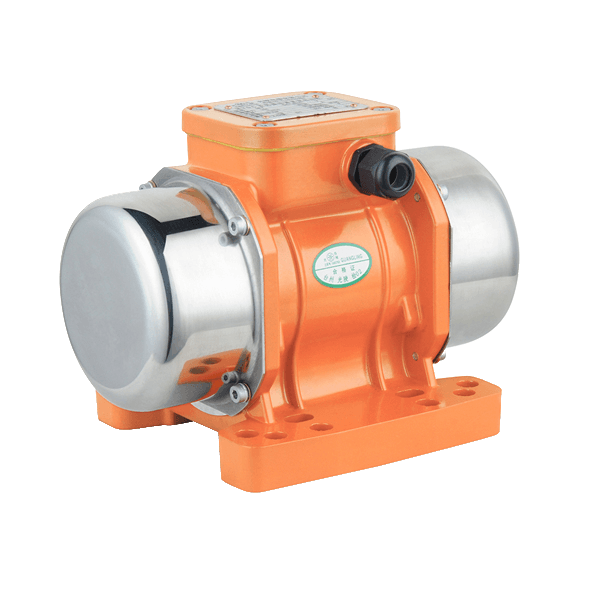

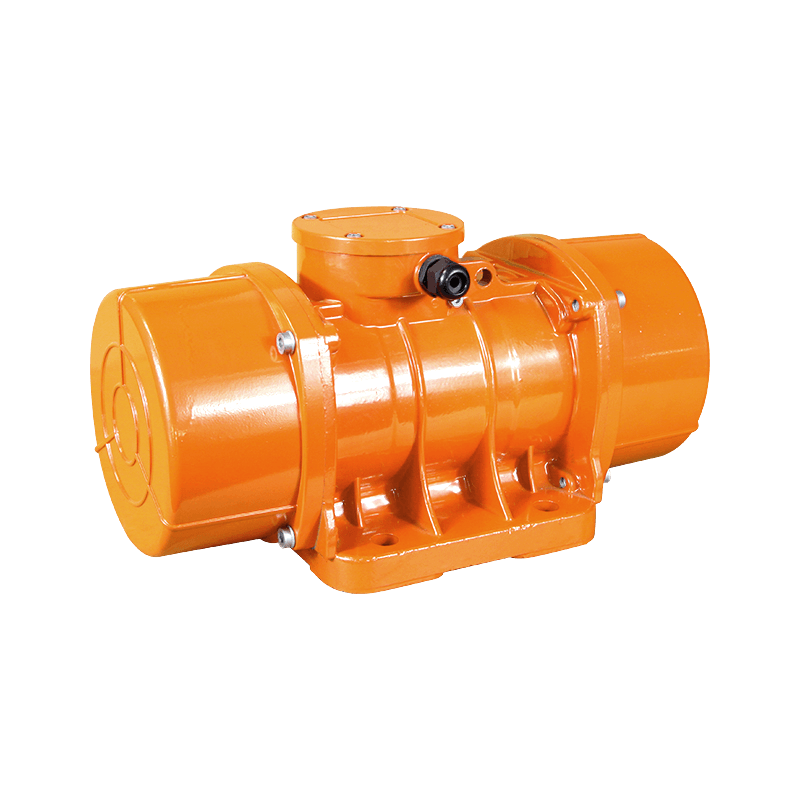

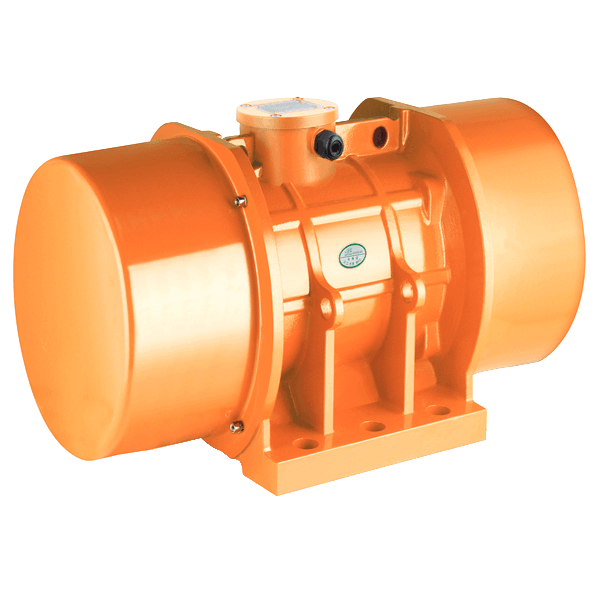

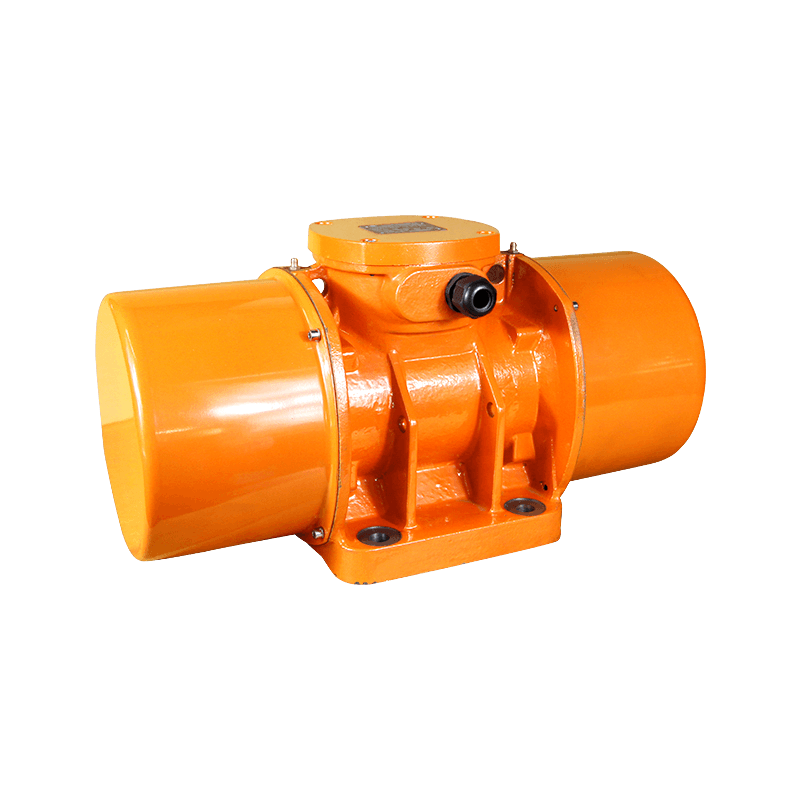

The vibrator is suitable for use in schools, scientific research, factories and other departments. It uses high-quality optical components and is equipped with ultra-large field of view eyepieces, epi-illuminators, flat field long working distance bright and dark field objectives, and is aimed at semiconductor wafer inspection and solar silicon wafer manufacturing. It is used as advanced industrial metallurgical microscope developed by industry, electronic information industry and metallurgical industry.

Vibrator can perform bright and dark field observation, epi-polarization, and is widely used in factories, research institutions, and universities to detect and analyze solar cell silicon wafers, semiconductor wafers, circuit substrates, FPD, and precision molds.

performance characteristics

1. Equipped with large field of view eyepieces and infinite long working distance plan achromatic objective lens (without cover glass), the field of view is large and clear.

2. Coaxial coarse and fine movement focusing mechanism, coarse movement and tightness adjustable, with limit locking device, fine movement scale value: 2μm.

3. Equipped with two sets of illuminating systems, epi-illumination and transmission, which can separately observe opaque or transparent objects.

4. The trinocular lens tube can freely switch between normal observation and polarized observation, and can perform 100% light transmission photography.

5. 6V20W halogen lamp with adjustable brightness.

The vibrator is a combination of optical microscope technology and advanced photoelectric conversion technology, which can not only manually observe metallographic images, but also can conveniently observe metallographic images on the The phase map is analyzed, graded, etc., and high-resolution metallographic photos can also be saved or printed.

Vibrator maintenance should pay attention to the following points:

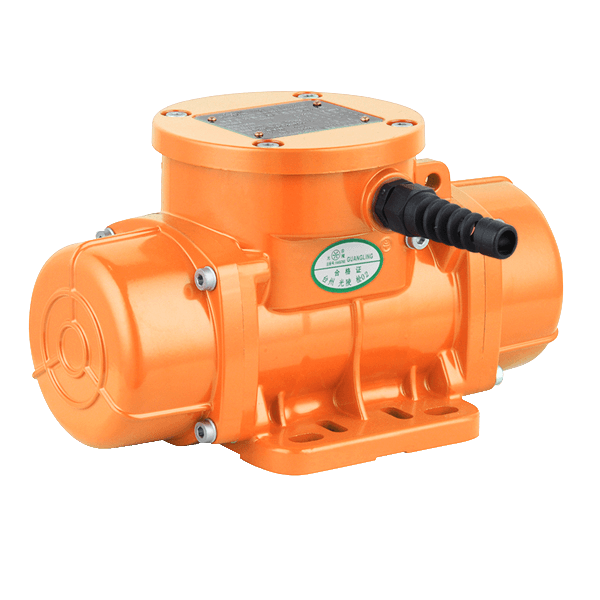

1, air supply

Compressed air containing moisture will rust the pipelines and fittings and affect performance, so pre-treatment should be done to keep it clean. Pneumatic vibrator piping and accessories should pay attention to selecting the appropriate specifications of high-current air conditioning combination, solenoid valve, and PU pipe to obtain complete air supply and give full play to its performance.

2, air piping

The air inlet and exhaust port of the vibrator should be determined in advance. The exhaust port can be equipped with a silencer to reduce noise and prevent dust from entering. The size of the air supply piping should match the size of the air inlet. When the two units are running simultaneously, the piping after the branch should be the same length, and the pipe before the branch should be twice the area of the piping.

3, lubrication

Most vibrators need to be lubricated, and a small amount of oil mist can make the movement smoother. Pour low-viscosity oil into the oil cup of the air conditioning unit to adjust the amount of oil.

英语

英语 葡萄牙语

葡萄牙语 西班牙语

西班牙语 русский

русский

Tel: + 86-576-86320988

Tel: + 86-576-86320988

Fax: + 86-576-86333217

Fax: + 86-576-86333217

E-mail:

E-mail:  Add: Dayangcheng Industrial Zone, daxi, wenling, zhejiang, china

Add: Dayangcheng Industrial Zone, daxi, wenling, zhejiang, china