Jun 01,2023

The electric vibrator motor is an electrical device that generates vibration for use in a variety of applications. It converts electrical current to mechanical motion through an electromechanical system and a magnetic field. It is used to agitate liquids and powders, move bulk solids in a conveyor line, or separate products in a bunker or landfill pipe. It also helps to maintain an even flow of material and reduces product loss due to a blocked chute or hopper.

There are a few basic types of motors that can be classified as vibrator motors: linear resonance motors, cylinder coreless motors, and coin vibration motors. They all share a common feature of being compact and lightweight. They can be powered by AC or DC current. The DC type of vibrator motor can be used with a battery for mobile devices like pagers and cell phones. They can also be powered by an AC adapter for powering vacuum tube radios and other electronic devices in cars, boats, and tents.

Vibration can be transformed into electric energy using electromagnetic dependent generators, which function on Faraday's law of induction and transform vibration into an electric field. This vibration can then be used to control the amplitude of a motor.

These devices are very popular for a wide range of applications, such as medical and commercial purposes. They can also be used to alert someone that there is an incoming call, or to warn people of danger. They can be made to vibrate in various ways, and the vibration can be directional or random. Some of these motors are even programmable to display different messages.

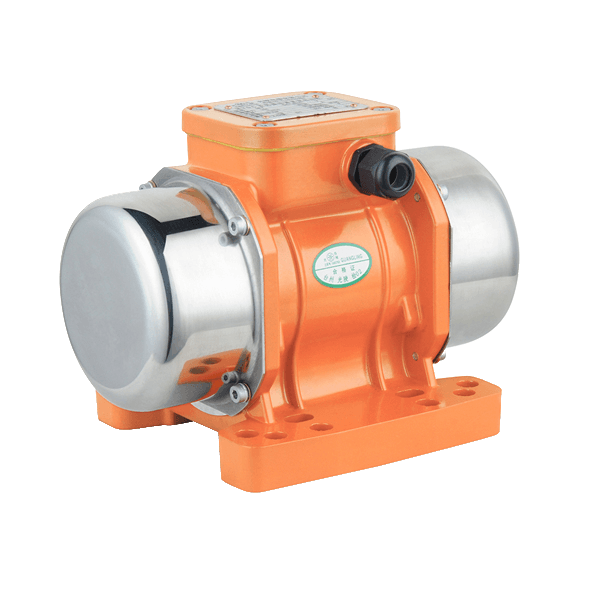

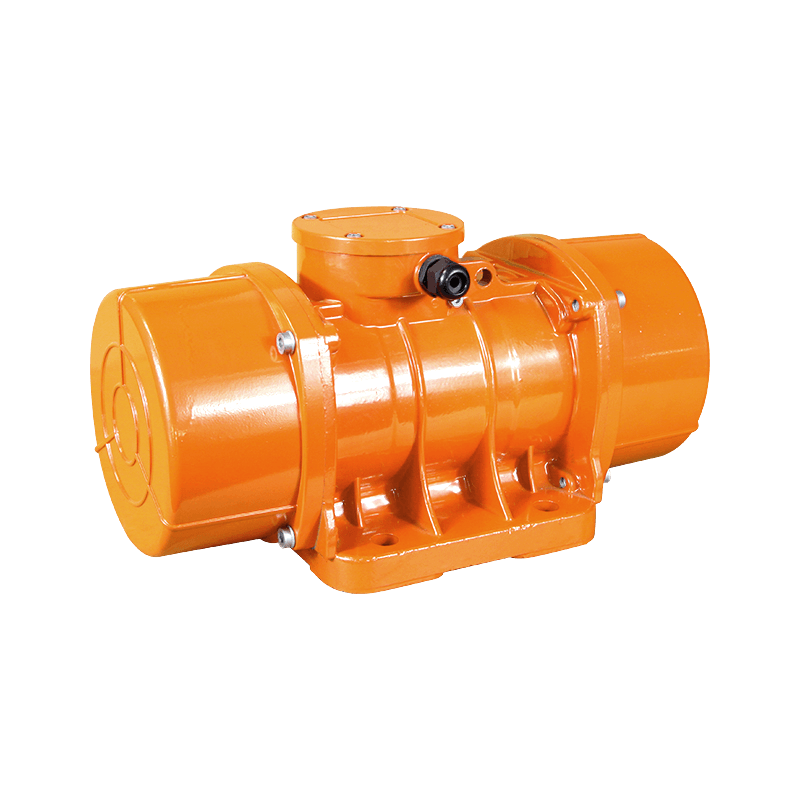

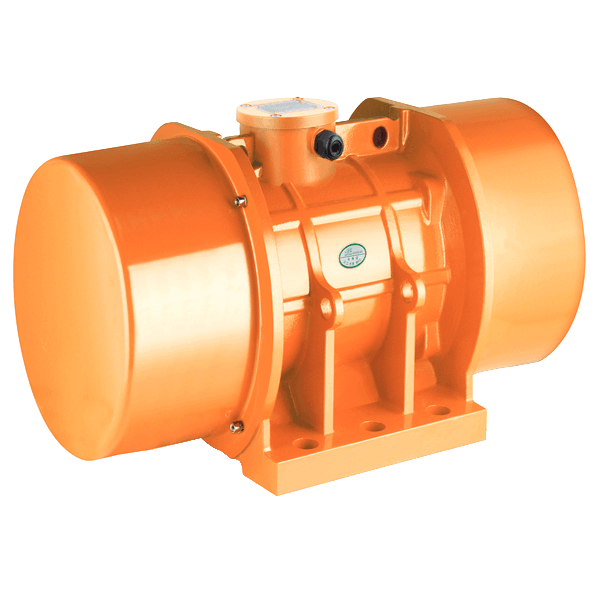

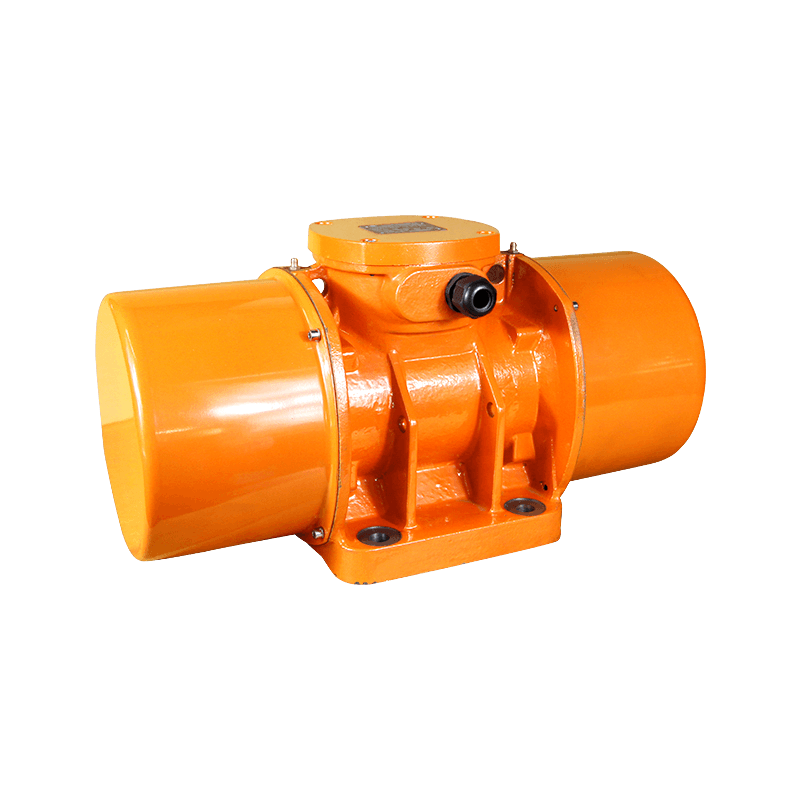

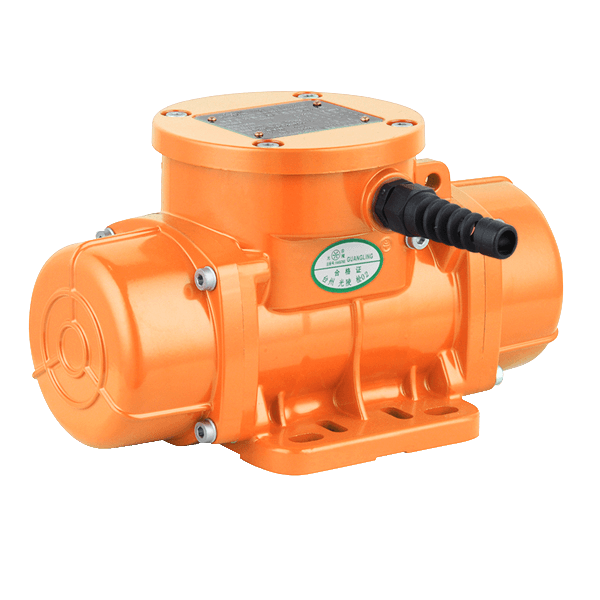

Electric vibration motors are available with a variety of armature styles, including stub shaft and shaftless designs. They can also be designed with heavy-duty construction for high-quality performance and long-life cycles. Many models have ductile iron castings and steel end covers for maximum durability and corrosion resistance. Some are also explosion-proof, making them a good choice for hazardous environments.

Depending on the design of the vibrator, the amplitude of vibration can be adjusted by changing the rated voltage or by the amount of current. The most important factors that determine a motor's amplitude are the weight mass, distance from the shaft, and the speed of rotation. Increasing the rated voltage will increase the vibration amplitude, while reducing the amplitude will decrease the speed of the motor.

The theoretical model above only considers a few degrees of freedom, so it is not appropriate for highly accurate predictions. Doubling the starting voltage will not necessarily double the speed, and some motors have very flat voltage/speed relationships, so their amplitude can change significantly even when the voltage changes. For more accurate estimates, it is best to perform a full experiment on the vibrator motor and compare the results with those of the simulation. The resulting correlation will provide the impedance, which can be used to calculate the current and displacement of the vibration motor.

英语

英语 葡萄牙语

葡萄牙语 西班牙语

西班牙语 русский

русский

Tel: + 86-576-86320988

Tel: + 86-576-86320988

Fax: + 86-576-86333217

Fax: + 86-576-86333217

E-mail:

E-mail:  Add: Dayangcheng Industrial Zone, daxi, wenling, zhejiang, china

Add: Dayangcheng Industrial Zone, daxi, wenling, zhejiang, china