Oct 29,2021

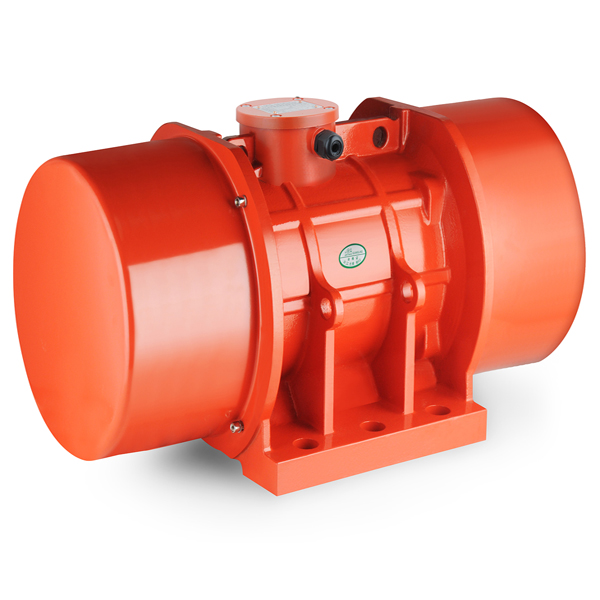

There is an electromagnetic coil in the electromagnetic vibrator, and the current passing through the electromagnetic coil is a pulse current that has been half-wave rectified. In the positive half-wave, the electromagnet has the attraction force and attracts the vibrating plate to approach; in the negative half-wave, the electromagnet has no current passing through, and the electromagnet's attraction disappears. Due to the action of the spring, the vibrating plate returns to its original position. The coal trough is connected with the vibrating plate, so that under the action of the electromagnetic vibrator, the coal feed trough continuously vibrates. Many vibration motor users always encounter a lot of problems during the second installation, mainly because the details of the installation are not well grasped. For these problems, we have summarized the problems that should be paid attention to when installing the vibrator.

1. Winding insulation. If it is damp, use corresponding methods to check the insulation resistance of the winding with a 500V megger. When it is close to the operating temperature (70°C), it should be no less than 0.38 megohm, otherwise it should be dried.

2. Whether the cable is in good condition, and if it is broken or damaged, it should be replaced in time.

3. Whether the body is in good condition, please contact us for replacement if it is damaged.

4. When installing the vibration motor on the vibration machine, the anchor bolts of the vibration motor must be tightened, and an elastic washer must be added under each nut.

5. In the early stage of operation of the vibration motor, due to the running-in between the bolts, nuts, and base planes, the tightening force will be reduced and small looseness will occur. Therefore, the anchor bolts of the motor should be tightened several times at the beginning of the operation, and tightened once a day at the beginning. Check the tightening once a week after two weeks.

6. The surface roughness of the connection between the vibration motor and the vibration machine should be 3.2 or higher. 1. The insulation of the winding, if it is damp, use the corresponding method to deal with the 500V megohmmeter. Check the insulation resistance of the winding, when it is close to the operating temperature (70℃) , It should be no less than 0.38 megohm, otherwise it should be dried.

7. The surface roughness of the connection between the vibration motor and the vibration machine should be 3.2 or higher.

After being installed in place, there must be a cable compression device on the body and its foundation. The cables between the two are naturally suspended, and the total length is preferably 300-500mm. Refer to the bending radius of the natural overhang. When the two vibration motors of the linear vibration equipment are working at the same time, check whether the rotation directions of the two vibration motors are opposite. Otherwise, the power phase sequence of one motor should be changed so that the direction of rotation of the two vibration motors is opposite to ensure the uniform direction of the material.

https://www.cnguangling.com/

英语

英语 葡萄牙语

葡萄牙语

Tel: + 86-576-86320988

Tel: + 86-576-86320988

Fax: + 86-576-86333217

Fax: + 86-576-86333217

E-mail:

E-mail:  Add: Dayangcheng Industrial Zone, daxi, wenling, zhejiang, china

Add: Dayangcheng Industrial Zone, daxi, wenling, zhejiang, china