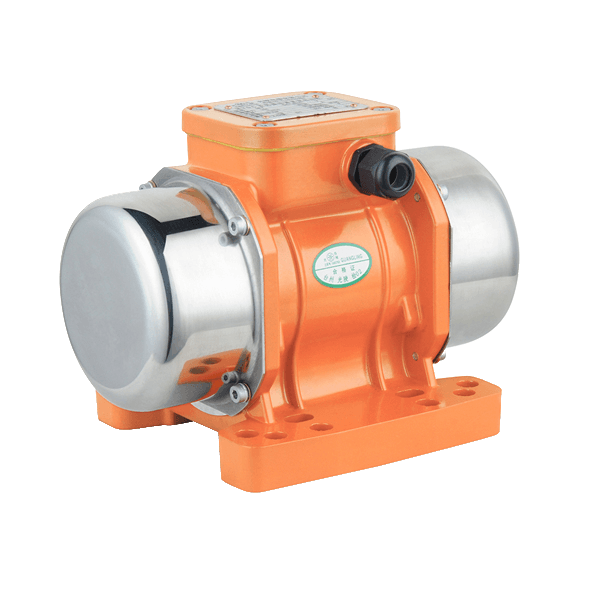

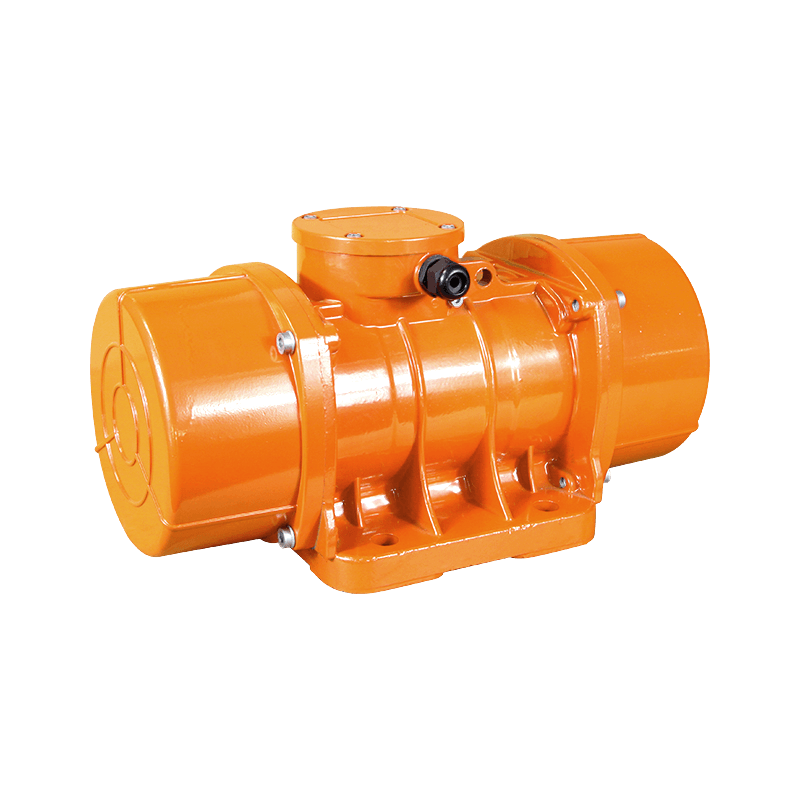

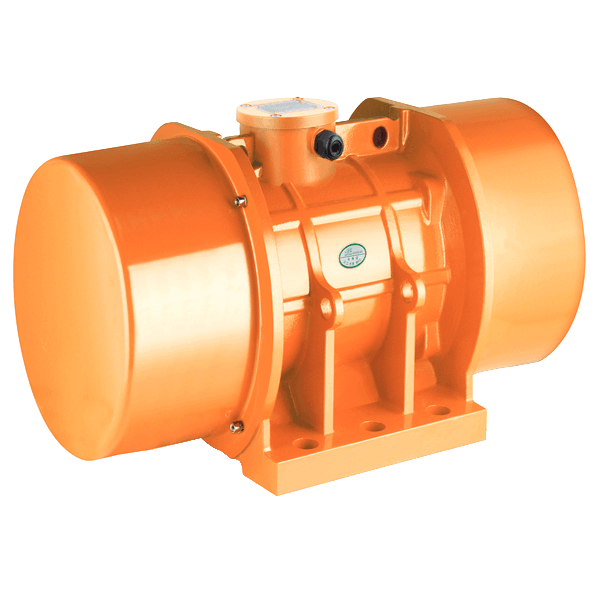

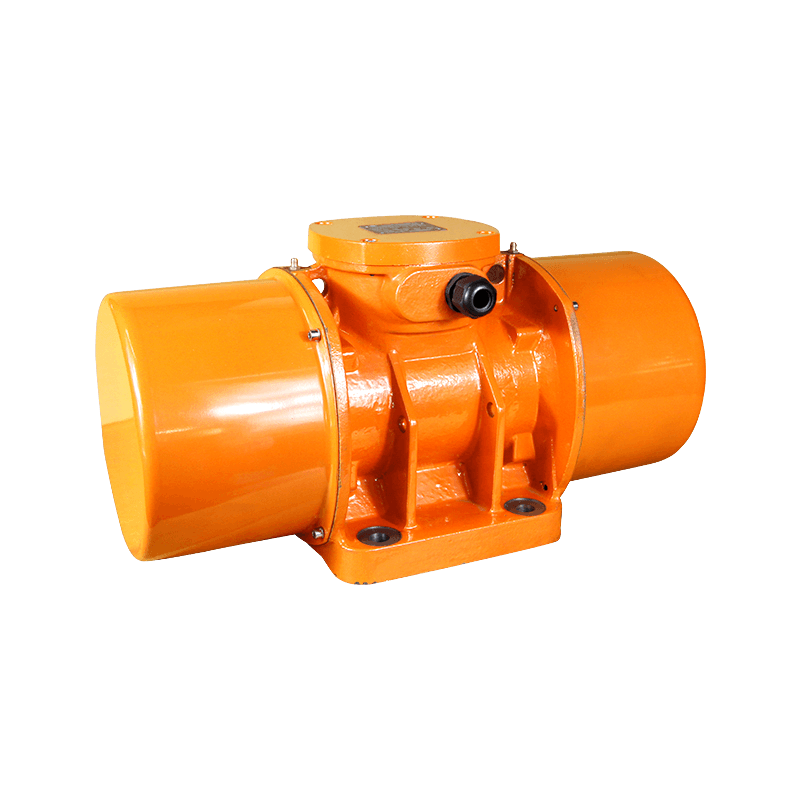

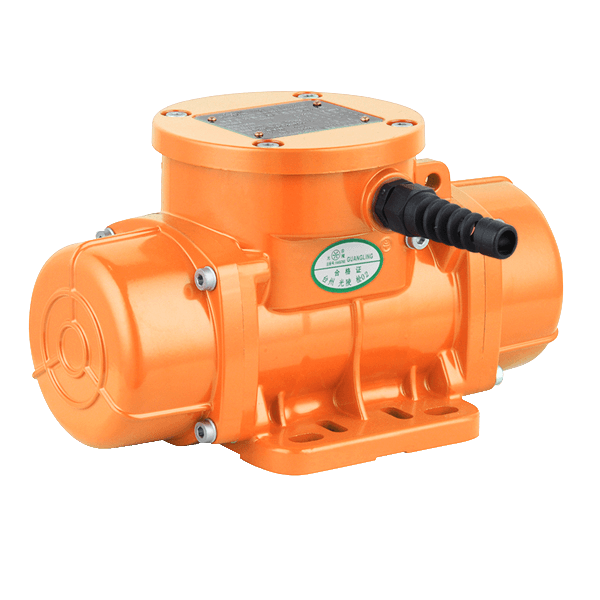

In the fast-paced world of industrial operations, from mining and chemical refining to construction machinery and material handling, the importance of precise and efficient equipment cannot be overstated. A crucial component that plays a significant role in a wide range of applications is the industrial standard vibration motor. These motors, known for their durability, reliability, and performance, are integral to enhancing productivity and ensuring smooth operations across several industries, including mining, chemical refining, construction, and material handling systems like conveyor belts and mixing stations.

Revolutionizing the Mining Industry

Mining operations require robust, heavy-duty machinery capable of withstanding the harsh conditions of the industry. Industrial standard vibration motors are pivotal in ensuring the efficiency and safety of mining operations. These motors are used in applications such as vibrating screens, shakers, and sieves to sort and separate materials with precision. The ability of vibration motors to induce specific frequencies ensures that particles are screened, classified, and sorted according to size and weight—critical tasks in mining that must be performed with high accuracy.

In addition to sorting and sifting, bin activators powered by industrial vibration motors are increasingly used in mining to prevent material build-up and ensure the smooth flow of bulk materials. Vibration motors dislodge material from bins, ensuring that the mining process remains efficient without downtime caused by blockages.

The tough working environment of mines requires vibration motors that are resilient and capable of handling high loads without failure. As mining operations expand, especially in remote locations, the reliability and longevity of vibration motors make them a vital part of mining machinery.

Enhancing Chemical Refining Processes

In the chemical refining industry, precise handling of materials is crucial. Industrial standard vibration motors have found a significant role in facilitating efficient mixing, blending, and material transport. In chemical processing plants, where consistency and uniformity are essential, vibration motors are used in mixing stations to ensure that ingredients and raw materials are combined thoroughly and evenly. This uniformity is essential for producing high-quality chemicals, pharmaceuticals, and petrochemical products.

The precise vibration action from these motors helps to create uniform flow patterns in reactors, accelerates mixing processes, and prevents clumping, to more efficient use of resources. Whether in bulk material transfer or during the critical step of reaction kinetics in chemical refining, vibration motors help increase throughput, reduce processing times, and enhance the overall performance of the plant.

Moreover, these vibration motors are used to activate bin dischargers to ensure that solids, powders, and liquids are efficiently and continuously moved in large-scale processing operations, eliminating the risk of material blockages and flow stoppages.

Empowering Construction Machinery

The construction industry is another sector that benefits greatly from the performance of industrial standard vibration motors. In construction machinery, vibration motors are essential in compaction and material handling applications. From vibrating rollers used in road construction to vibratory plates in trenching, these motors help to compact loose soil, gravel, or asphalt to achieve the required density and uniformity.

Construction machinery equipped with industrial vibration motors also uses these motors in the excavation and concrete pouring processes. When handling large loads, vibration motors ensure that materials are properly settled and compacted, reducing the chances of air pockets or uneven surfaces. The result is more stable infrastructure, ensuring long-term durability and safety.

Additionally, industrial standard vibration motors play a critical role in piling machines and drilling rigs by stabilizing machinery, reducing vibration-induced wear, and increasing the operational lifespan of these heavy-duty construction tools.

Optimizing Conveyor Belt Vibration Systems

The material handling sector, including conveyor belt systems, greatly benefits from the use of industrial standard vibration motors. Conveyor systems are often used to transport large quantities of bulk materials in industries like mining, manufacturing, and agriculture. When combined with vibration motors, these systems improve material flow, reduce jams, and enhance overall efficiency.

英语

英语 葡萄牙语

葡萄牙语 西班牙语

西班牙语 русский

русский

Tel: + 86-576-86320988

Tel: + 86-576-86320988

Fax: + 86-576-86333217

Fax: + 86-576-86333217

E-mail:

E-mail:  Add: Dayangcheng Industrial Zone, daxi, wenling, zhejiang, china

Add: Dayangcheng Industrial Zone, daxi, wenling, zhejiang, china