Sep 14,2022

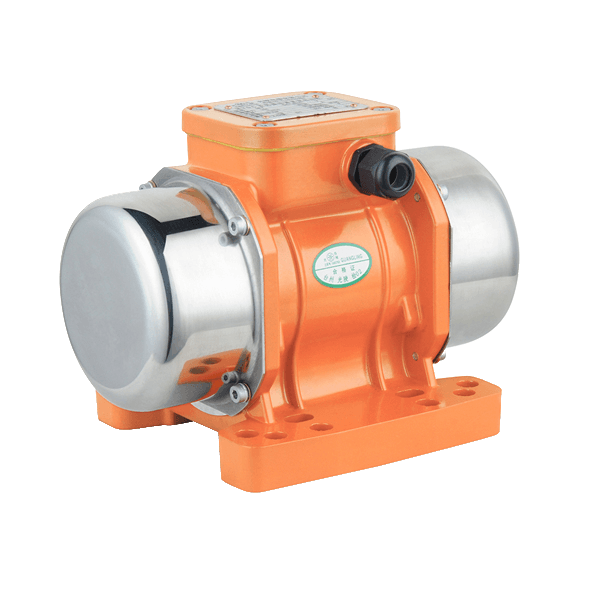

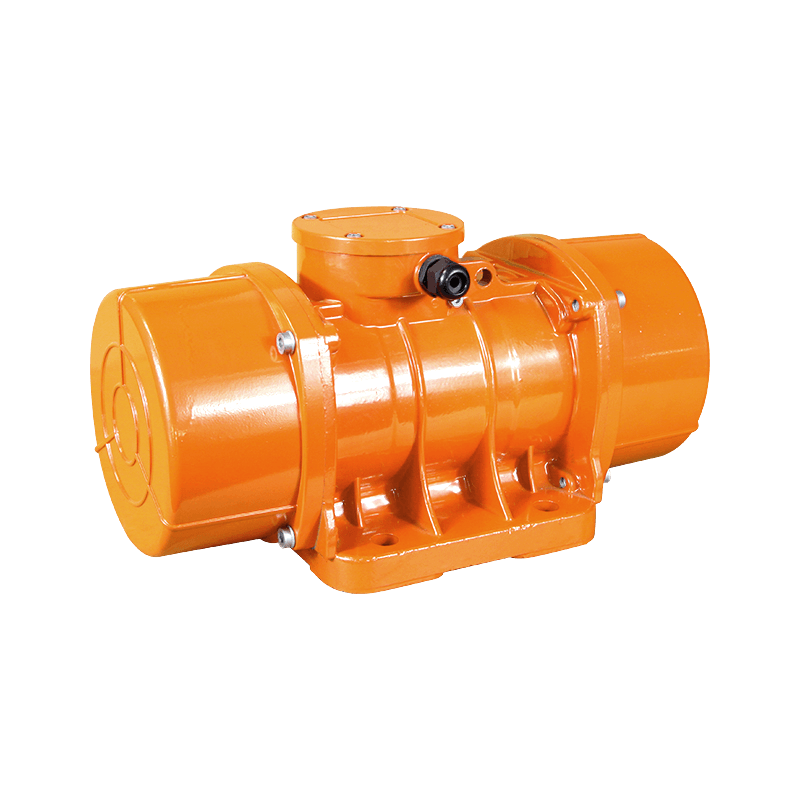

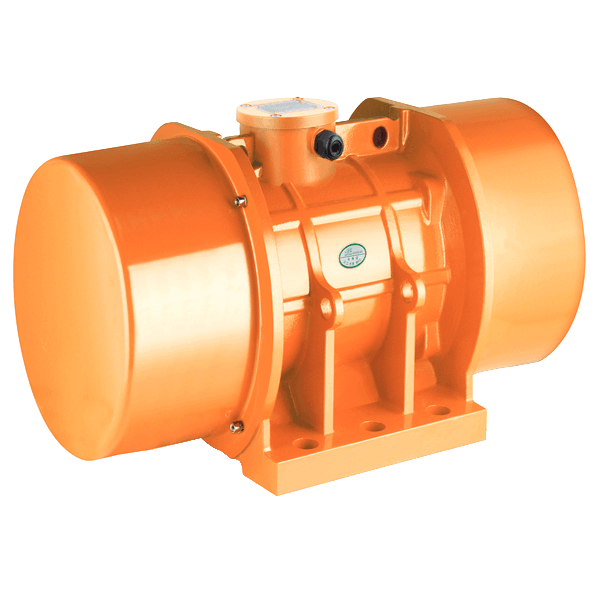

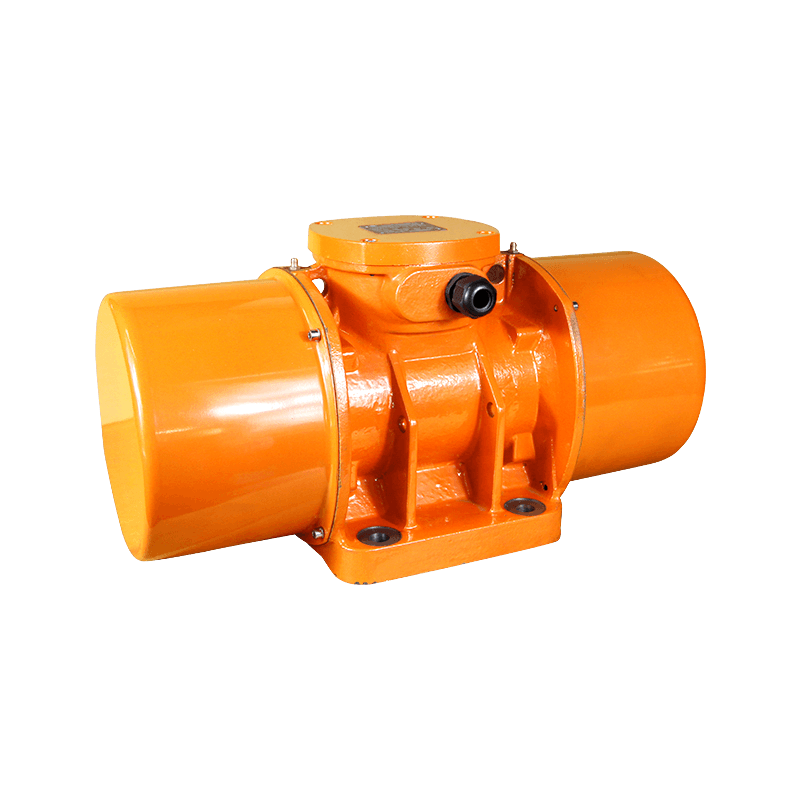

Vibration motor conveying equipment can provide a number of benefits to a material-handling system. These conveyors can handle most types of bulk materials, including powders and solids. They can also handle irregular-shaped materials. This is why vibrating conveyors are used in a wide variety of processes.

The vibrating conveyor is an excellent choice for bulk materials that need to move quickly and accurately. They can be sized to be up to 5 meters long and come with a variety of options. They can be designed with tubular designs or open troughs, and are constructed using carbon steel or stainless steel.

Standard duty vibrating conveyors are typically designed for materials with a medium density. They can move between one and 40 tons of material per hour and travel at speeds up to 60 feet per minute. They are portable and modular, and have relatively low wear and tear. They find application in many industries, including foundries and plastics.

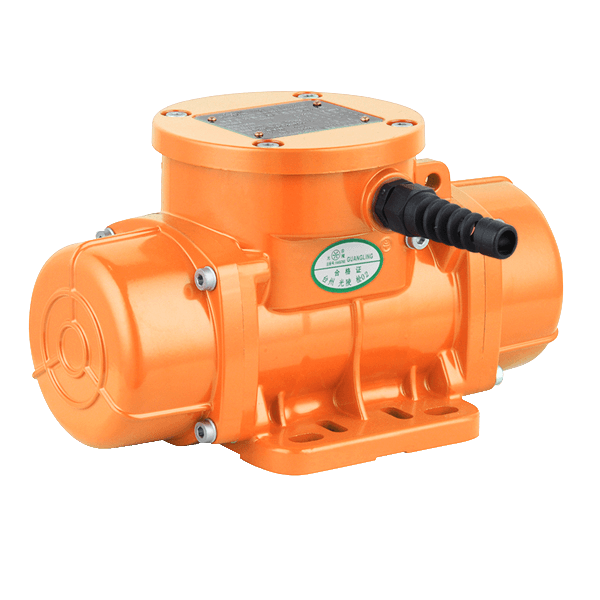

Variable speed feeders are another option for conveying materials. These vibratory feeders are generally cheaper than their electromechanical counterparts, and can be used in hazardous areas. This is because they have fewer moving parts. These vibratory feeders are also generally suitable for low volumes of materials, and they can be cheaper for less-than-five tons per hour. They also require explosion-proof specifications.

英语

英语 葡萄牙语

葡萄牙语 西班牙语

西班牙语 русский

русский

Tel: + 86-576-86320988

Tel: + 86-576-86320988

Fax: + 86-576-86333217

Fax: + 86-576-86333217

E-mail:

E-mail:  Add: Dayangcheng Industrial Zone, daxi, wenling, zhejiang, china

Add: Dayangcheng Industrial Zone, daxi, wenling, zhejiang, china